I would like to use that wonderful piece of canari wood to try my hand at making a more traditional wooden bass. I want it to be special in some way.

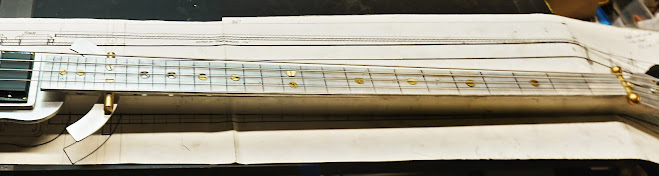

I considered using 5 single tuners to make it a 5 strings long-scale bass using extra long strings, possibly pushing the scale to 38". But then I ran across a really nice set of tuners and string locking nut on Amazon for only $35.99... I was not expecting much, but it turned out really nice and solid, and I decided to use it and go for only 4 strings.

On top of that, the way the individual bridges are designed, I could with minor modifications place a piezo pickup right under them. All I had to do was to cut 2 slots on the sides to accommodate the width of the piezo and one underneath for the wire:

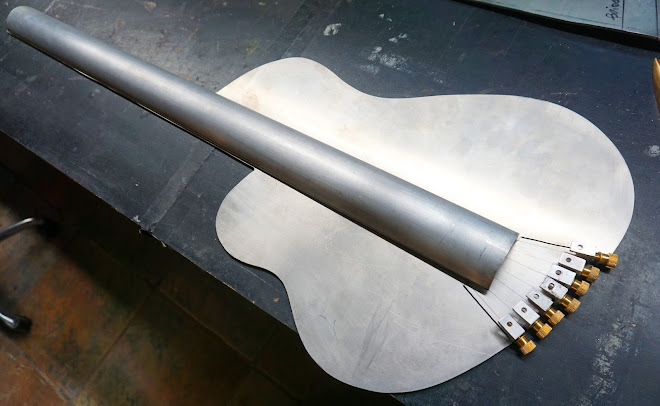

I had first made a rough mockup in Photoshop:

The length of the neck will be determined by the length of the strings, and I want big strings, so I ordered a set of 5 D'Addario Xtra Long flat-wound bass strings, of which I will only use the 4 bigger ones .65, .80, .100 , and .132.